- Home

- Equipment Reviews

-

Amplification Digital Integrated Mono Block Preamplifier Phono Solid State Tube Analog Sources Cartridges Tape Tone Arms Turn Tables Digital Sources Digital Disc Players DACs Music Servers Streaming Music Services

-

Accessories Power Conditioners Room Accoustics Racks & Stands Audio Software Other iPod iPod Speakers iPod Headphones iPod Transports Headphones Over Ear On Ear In Ear Headphone Amplifier

-

- Audio News

- Event Reports

- California Audio Show, San Francisco

- Consumer Electronics Show

- T.H.E. Show

- Rocky Mountain Audio Fest

- AXPONA

- Salon Son & Image

- Hi-Fi Show & AV Expo

- High End

- Lone Star Audio Fest

- Capital Audio Fest

- TAVES - Toronto Audio Video Entertainment Show

- AK Fest

- Home Entertainment Show

- New York Audio $ AV Show

- Open House Events

- Spotlight

- Music

- The Columns

- 2024 California Audio Show

Latest Reviews & Audio News

-

Technics SU-R1000 reference stereo integrated amplifier Review

(April 5, 2024) -

Computer Audio Design GC 1.1 & GC3.1 Ground Control external grounding systems Review

(April 5, 2024) -

Andy Grove of Audio Note UK on IO LTD

(March 23, 2024) -

Audio Note UK IO Limited field-coil cartridge system Review

(March 26, 2024) -

EMM Labs MTRX monoblock Input Board Upgrade Review

(March 7, 2024) -

May 2018 Sibelius Violin Concerto concert video via Berliner Philharmoniker Digital Concert Hall app

(February 16, 2024) -

Aurender N20 Ultra High Performance digital output network transport Review

(February 15, 2024) -

Benchmark Media AHB2 THX AAA stereo amplifiers Review

(January 18, 2024) -

Nelson Pass Interview 2023

(December 6, 2023) -

Interview with singer, pianist Fiona Joy Hawkins and singer, violinist Rebecca Daniel at 2023 CAS

(October 10, 2023) -

Aurender A20 reference analog output network player Review

(September 27, 2023) -

Acoustic Energy AE100² bookshelf speakers Review

(September 11, 2023) -

Clarisys Audio Minuet planar ribbon speaker system Review

(August 19, 2023) -

Clarisys Audio Interview

(August 7, 2023) -

Bricasti Design M21 dual-mono DSD, Ladder and Delta Sigma DAC Review

(December 9, 2023)

-

Categories

-

Amplification Digital Integrated Mono Block Preamplifier Phono Solid State Tube Analog Sources Cartridges Tape Tone Arms Turn Tables Digital Sources Digital Disc Players DACs Music Servers Streaming Music Services

-

Accessories Power Conditioners Room Accoustics Racks & Stands Audio Software Other iPod iPod Speakers iPod Headphones iPod Transports Headphones Over Ear On Ear In Ear Headphone Amplifier

Site Sections

Copyright ©1996-2024 All Rights Reserved.

Popups Powered By : XYZScripts.com

I had the afternoon off from work today and nearly completed the job of moving the bicycle from its winter storage alongside my bed (you have to be a townhouse-dweller to understand) to its seasonal placement on a hook by the backdoor. It’s a job because boxes and boards and other winter hallway pile-ups had to be moved as well. I sleep in one bedroom, you see, and have the drill press, chop saw, and numerous other tools at work in the other. Nearly completed because, inevitably, there is the odd box or bit that isn’t underfoot and can wait until another CD or LP or nine is heard.

I was left with 3 framed movie posters and a 2’x4’x2” thick fiberglass panel behind the right speaker. This panel is the last of a six-pack I ordered from ATS Acoustics to finally sound-condition my listening room. The CD was the brilliant Mapleshade recording of Alan Gampel playing Liszt and Chopin Sonatas. All the way through the Chopin Sonata No. 3 there was a no-doubt discontinuity of the bass from the treble as though a madman sat at the mixing panel twisting and turning the pots and faders at random. Could this be the panel behind the speaker?

I had this one panel remaining because, A) I had run out of burlap and, B) I had arrived at a point in my sound-conditioning experiment that satisfied my listening needs. This had to be the culprit because nothing else had changed since my last listening session. I moved it out from behind the speaker and placed it waaay up on top of the 70” tall bookshelves on the front wall where it just fit between top shelf and ceiling.

I sat back down and remoted the “Finale: presto, non tanto” of the Chopin back to life. All the notes were back where they belonged and as a bonus, the upper treble was smoother and more liquid. These changes are not the “which hummingbird wings” subtleties of cables or connectors. They are repeatable, yield to measurement and are heard by everyone. Best of all, you don’t need any microphones or signal generators and these improvements cost hundreds, not thousands of dollars.

ATS Acoustics and others will sell you finished panels in a wide choice of fabric coverings. There are other companies that have proprietary shapes and fillings that also accomplish this task. But for a poor someone like myself, the cost always pushed the job back behind another pair of compression drivers or selection of veneer. Giving credit where it is due, I was impressed by our own Laurence A. Borden’s recent experience with Rives Audio and serendipitously, soon after his article appeared I read a post on the Tweaker’s Asylum about room treatment. Kal Rubinson of Stereophile directed a poster to Sensible Sound Solutions who sell the same sort of sound panels along with raw fiberglass panels. Along the way I visited Ethan Winer’s Forum sponsored by Rivesaudio.com. There, I found a trove of information for do-it-yourselfer’s from some of the most unselfish folks in audio.

I determined that Owens-Corning 703 rigid fiberglass panels were just what I needed. That and a lot of colored burlap, poly-fill batting and 1/4” plywood cut to size. ATS sent me the aforementioned box of 6 panels for $92 to my door; the $10 sheet of 1/4” plywood I brought home from work. The difficult part was invading the womanly lair of Jo-An Fabrics. Nothing I like better than being condescended to by a woman who sees her chance to humble a male out of his element. After selecting yards of blue and red and “that’s oatmeal, not tan” burlap, I hastened out of there less $32 and went to work.

My research led me to believe that I already had a foundation with a 60” X 72” bookcase full of books between the speakers on the front wall, and a ’floating’ 12” deep by 14” by 72” case above the sofa on the rear wall. These would do as diffusers. I wanted to leave the front wall somewhat live and deal with the rear wall and its corners. I constructed 4 panels measuring 24” X 48” each and 2 panels of 24” X 24” to start. It’s just a matter of cutting the burlap roughly to size then laying it on the work surface followed by the batting, then the 703 panels and finally the plywood. I stretched the burlap onto the plywood just like you would repair a screen except I folded it back on itself to better hold the 3/8” staples.

I first tried both 24” X 48” and 24” X 24” panels behind the speakers and the remaining 2 large panels on the rear walls. That was too absorbent. I left the small panels behind and above the speakers and moved 2 large panels to the rear wall flanking the ‘floating’ LP storage case and another to the ‘first reflection point’ of the right hand speaker. The left hand speaker does not have an adjacent corner wall. This ‘first reflection point’ is found by having another person move a mirror along the adjacent corner wall until you can see the speaker reflected from your listening position. There are also ‘first reflections’ at the floor and ceiling. All my reading and reference to the Rives’Forum shows that these points are key and you move along to the rest of the room only after dealing with them. The last piece of the puzzle was piling 3- 40 sq. ft. rolls of R-13, still in the plastic but also disguised with burlap, in the corners. These function as ‘bass traps’, ameliorating standing waves and flattening bass humps. They have been long recommended By Jon Risch and are whole-heartedly endorsed by Ethan Winer.

The results of this cut-and-fit process are mind-boggling. I achieved an enormous improvement in mid-range clarity, treble purity and instrument placement. My pal Speakerman has been nagging and nagging me to do something about the overloaded mid-range in my room. And he was, as usual, so right! Will you hear a difference? Will visitors? I can reach up and take just one panel off the wall and hear a difference. Friends with MP3’s and IPods come in and we move them about and they’re amazed by what they’re hearing.

You know how it’s considered good form to end an audio BBS post recommendation with YMMV (your mileage may vary)? And even professional reviewers insert caveats in their pronouncements. Well, whether you hire Rives, take a shot at a package of ready-made panels or build your own like me, your mileage will NOT vary and there are no caveats. You already have some room treatment. More treatment with sophisticated materials like the Owens-Corning 703 will yield impressive results. And as Ethan Winer says of Bass Traps: “you can’t have enough!”

Bill Epstein’s system:

CD Player: Sony SCD-CE 775 with SACDMods.com

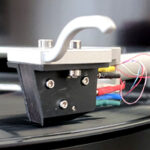

LP system: Ariston RD-11Superieur/SME 3009R II/ Dynavector 10×5

No pre-amp

Hagerman Bugle Phono-stage

Amplification: Audio Note Kit 1 300B; KR Audio VA 240 300BXLS

Speakers: 3 Way Bass reflex/horn combination adapted from a Wayne Parham, Pi Speakers design

* JBL 2226J 15″ mid-woofer to 1600Hz, Altec-Lansing 902B 1″ compression driver on 800Hz Martinelli Woodhorns.com horns, Vifa DX 25 at 13000 Hz

IC’s are those nice blue one’s by AR from Best Buy and speaker cable is Royal Cable, 14ga rope lay copper you get at Wal-mart in the auto parts section – Right next to the goldfish and parakeets.