The turntable comes with two interchangeable drive wheels which fit onto the top of the motor shaft which protrudes from the housing, and lock in place with a simple set screw. The drive wheel for the rim drive operation has a pure silicone drive ring around its circumference, whereas the one for belt-drive operation has three grooves, one each for the three belts. In either case, drive is provided to the 13.5-inch acetal rim, which is specially designed for this purpose. The drive is mated to the main platter with special tension fit installation, which provides a mechanical decoupling from the driven rim to the record platter.

The motor controller is separate from the motor, and connects to it via an umbilical. The controller is powered by a small switching power supply; the latter makes a tiny bit of noise, as does the motor, but neither is audible unless one is standing right next to it. In addition, LD has informed me that a new motor casing is available as an option to further eliminate any motor noise. On the rear of the controller are two switches; one is a power switch, the other changes motor direction, so as to accommodate both rim- and belt-drive. On the front of the controller are three dials and one toggle switch. The leftmost dial is the SELECTOR for 33/13 and 45 rpm operation. To its right is the ON/OFF switch. To its right are two switches, one each for fine-tuning the speed for 33 1/3 and 45 rpm operation. The controller specs are as follows:

· Silent Drive™ Ultra Duo-Drive Controller

· Duo Drive Selection (rear panel select belt or rim mode)

· Speed selector 33.333/45 rpm (78 can also be set)

· Platter ON/OFF aircraft grade power switch(s)

· Separate speed control (10x Fine pots) for 33.333 and 45 rpm

· Power Supply is a Universal Voltage 100 to 400V transformer

· 6.5 AMP, 24 Volt output Built in AC line filters for extreme low noise

· XLR connector and standard HD grounded power cord 4ft

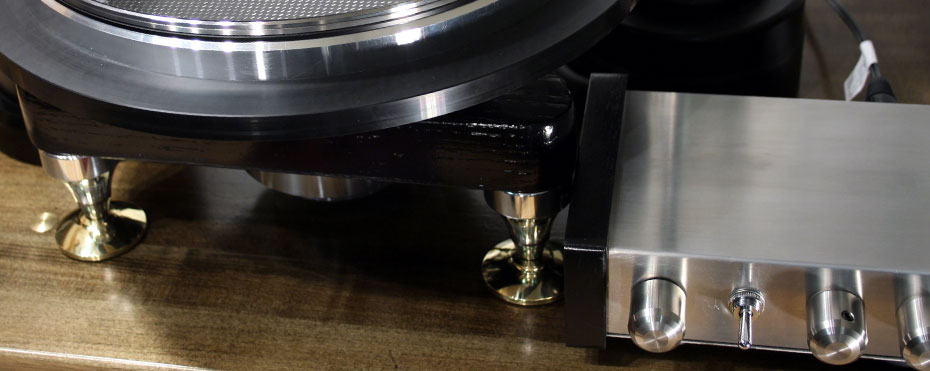

As noted above, the arm pod is external to the plinth. As such, the ‘table can accommodate arms of any length, and changing to an arm of a different length poses no difficulties. Moreover, the design allows one to add additional arms at any time, the only limitations being the size of the rack and depths of one’s pockets. The arm pods are solidly constructed, and have at their bottom an O-ring similar to that on the motor. Between the pod’s own weight and the sealing action of the O-ring, the arm remains firmly in place. Smart! The top of the arm pod is fitted with an adaptor to which the tonearm attaches. When a GEM is ordered, TTWeights can provide pre-machined arm pod caps for the customer’s tonearm, or the customer can do so himself. LD assured me that this is a simple process, requiring nothing more than a basic electric drill. Moreover, attaching the adaptor to the pod is simple. Smart again.

Start Me Up

LD and his lovely wife Christine made the ten-hour drive each way from Toronto to New Jersey to deliver and assemble the GEM. LD is, of course, quite adept at this, the process is simple and straightforward. Because of the modular design, no part weighs more than 22 lbs. Each part is individually packaged. In addition to the printed instructions, LD has posted a series of YouTubes which demonstrate the assembly process. The YouTubes were made with an earlier model, but the main steps are the same. First, one must position the plinth so as to provide adequate room for the motor and arm pod(s). Accordingly, we placed the table directly on my slate rack; for those who have lighter racks, and for whom vibration is a special problem, a special wooden platform is available from TTWeights. The platforms is available in ash, maple or oak, and can be made in any size (18” x 24” is recommended), and is placed between the GEM and the rack.

The platter is next placed on the plinth, care being taken to ensure the bearing seats properly. The turntable is pre oiled and need not be lubricated for 2-4 years. The Oilite is self lubricating, so the oil is just insurance.

The table is leveled by adjusting the three footers. One first screws in the pre-assembled TTSoundPoints, and places them on the TTSoundPoint Base; the latter have O-rings to protect the mounting shelf, and to prevent the table from shifting, similar to the motor design. Each Sound Point has a retaining ring which, when lifted, allows the footer to be rotated, thereby raising or lowering it. Once the correct position is obtained, one re-locks the retaining ring. Easy and effective!

- ← Previous page

- (Page 3 of 4)

- Next page →

Hello, does anyone know of an excellent electronics repair shop. I have this turntable with the upgraded speed control, both rim drive and belt drive capable. TTWeights no longer able to repair, service their turntables. Thank you kindly. Derrick

Any one know where to get the schematics to repair the speed controllers?

I have a TTW Momentus V 2 and love it. I had the motor control stop working and it was a simple blown fuse on the motor driver board. My friend is an EE who works for a company that sells components and designs motor controllers, etc. It was a $1.00 fix. But, if you have the “Silent Drive”, here is the link to the motor, including driver, that TTW used. I know this cause he posted a picture of it on Audiogon, I blew up the image and pulled the ID off the picture of the driver (although the one posted was the 30 W driver and not the 50 W drive for the 50 W, 1/15 HP motor).

https://catalog.orientalmotor.com/item/blh-series-brushless-dc-motor-speed-control/50w-blh-brushless-dc-motor-speed-control/blhm450kc-a-blh2d50-k

NOTE: the motor is almost surely not blown, it is something to do with the board. You could simply unplug all the Molex connections and swap in the new board for around $180.00 with taxes and shipping.

I am building a new unit and keeping the old one as a back up. With better switches and pots in a new case. The board is $150, the I/O -power wiring harness is like $10, the motor extension cable was like $89 with shipping, the aluminum case was $33 (Amazon), better pots $60, and the various inputs etc., unless you want to scavenge from the old unit, will run about $340.00.