What’s Old is New Again

The function of a turntable is conceptually simple to describe: Allow the cartridge and arm to accurately transduce the information contained within a record’s grooves. The means to accomplish this are similarly simple to describe; the turntable will: (1) spin the platter at a carefully regulated speed, (2) not inject any mechanical (or electrical) noise into the system that might be picked up by the cartridge, and (3) be impervious to external mechanical vibration. Unfortunately, putting these into practice is far from trivial.

In the earliest turntables, the motor was mechanically coupled to the platter, either directly (i.e., “direct drive”) or via an idler wheel. Unfortunately, such designs transmitted considerable mechanical noise, as a result of which they were largely replaced by belt-drive turntables, which to this day remain the most common type of turntable amongst audiophiles (as opposed to DJs, for whom direct drives predominate).

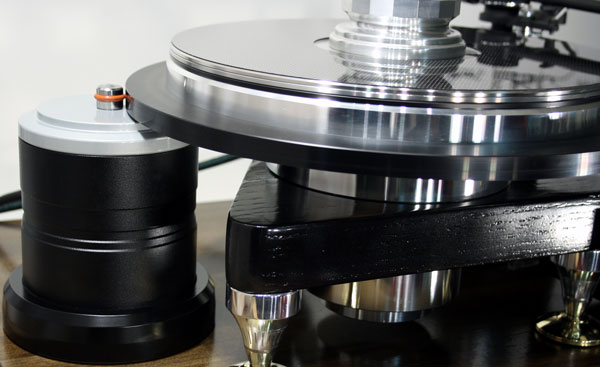

Belt-drive tables are generally quieter than direct-coupled turntables, and recent efforts to improve their speed control include more accurate motors and controllers, the use of multiple motors, and different belt materials. In this review, I will use the term “direct coupled” to include direct drive, rim drive and idler wheel drive; in short, any mechanism other than the belt-drive design. While there are many excellent belt-drive tables on the market today, at a variety of price points, there exists a contingent of audiophiles who nonetheless feel that the such designs are inferior to direct-coupled drives in terms of dynamics and “slam.” As such, the last decade or so has seen a resurgence of interest in vintage direct drive and idler wheel turntables, such as Technics SP10, Garrard 301, 401 and 501 and Lenco’s (amongst other), and considerable efforts have gone into finding ways to make these tables operate as silently as possible. First and foremost was the recognition that such tables, with their generally large motors in close proximity to the platter, require heavy, well-damped plinths. Toward that end, numerous hobbyists, and more recently some commercial ventures, have designed plinths using a variety of materials, with Panzerholz and slate garnering particular praise.

Modifications did not however end with the plinth; enthusiasts found that performance could be further improved by bringing to more modern specifications the bearings, top plates, idler wheels and linkage, platters, arm boards, motor controllers, and even the motor itself. In short, nearly every portion of the turntable has, in one model or another, been modified or replaced in toto. The question that obviously comes to mind is, why not build a new table from scratch?

Out With the Old, in With the New

Larry Denham, owner of TTWeights, worked in the family business, TDP Aerospace, from 1980 until its sale in 2000. He then worked as a consultant for a few years and began LJT manufacturing with his wife Christine in 2004. LJT is located about 70 km north of Toronto, and is a precision machining company that provides parts and service to the aerospace industry. LD has been an audiophile for most of his life and not surprisingly given his background, has a particular fascination with turntables. In 2007, he decided to apply his manufacturing and design skills to turntables. His first products were center clamps and outer rings, from which the company name TTWeights was derived. These products were well received by the audiophile community, providing the impetus for LD to build a turntable. From scratch.

- (Page 1 of 4)

- Next page →

Hello, does anyone know of an excellent electronics repair shop. I have this turntable with the upgraded speed control, both rim drive and belt drive capable. TTWeights no longer able to repair, service their turntables. Thank you kindly. Derrick

Any one know where to get the schematics to repair the speed controllers?

I have a TTW Momentus V 2 and love it. I had the motor control stop working and it was a simple blown fuse on the motor driver board. My friend is an EE who works for a company that sells components and designs motor controllers, etc. It was a $1.00 fix. But, if you have the “Silent Drive”, here is the link to the motor, including driver, that TTW used. I know this cause he posted a picture of it on Audiogon, I blew up the image and pulled the ID off the picture of the driver (although the one posted was the 30 W driver and not the 50 W drive for the 50 W, 1/15 HP motor).

https://catalog.orientalmotor.com/item/blh-series-brushless-dc-motor-speed-control/50w-blh-brushless-dc-motor-speed-control/blhm450kc-a-blh2d50-k

NOTE: the motor is almost surely not blown, it is something to do with the board. You could simply unplug all the Molex connections and swap in the new board for around $180.00 with taxes and shipping.

I am building a new unit and keeping the old one as a back up. With better switches and pots in a new case. The board is $150, the I/O -power wiring harness is like $10, the motor extension cable was like $89 with shipping, the aluminum case was $33 (Amazon), better pots $60, and the various inputs etc., unless you want to scavenge from the old unit, will run about $340.00.